· ·

Specifications

Ø

Dispersing Capacity:

Designed to efficiently disperse and dissolve

materials in liquid or solvent.

Available in

various capacities to suit different batch sizes and production requirements.

Ø

Motor Power:

Powerful motor for

effective dispersion and creation of high shear forces.

Motor power

options may vary (e.g., 2 HP, 5 HP, 10 HP, etc.) based on the specific agitator

model and desired dispersion intensity.

Ø

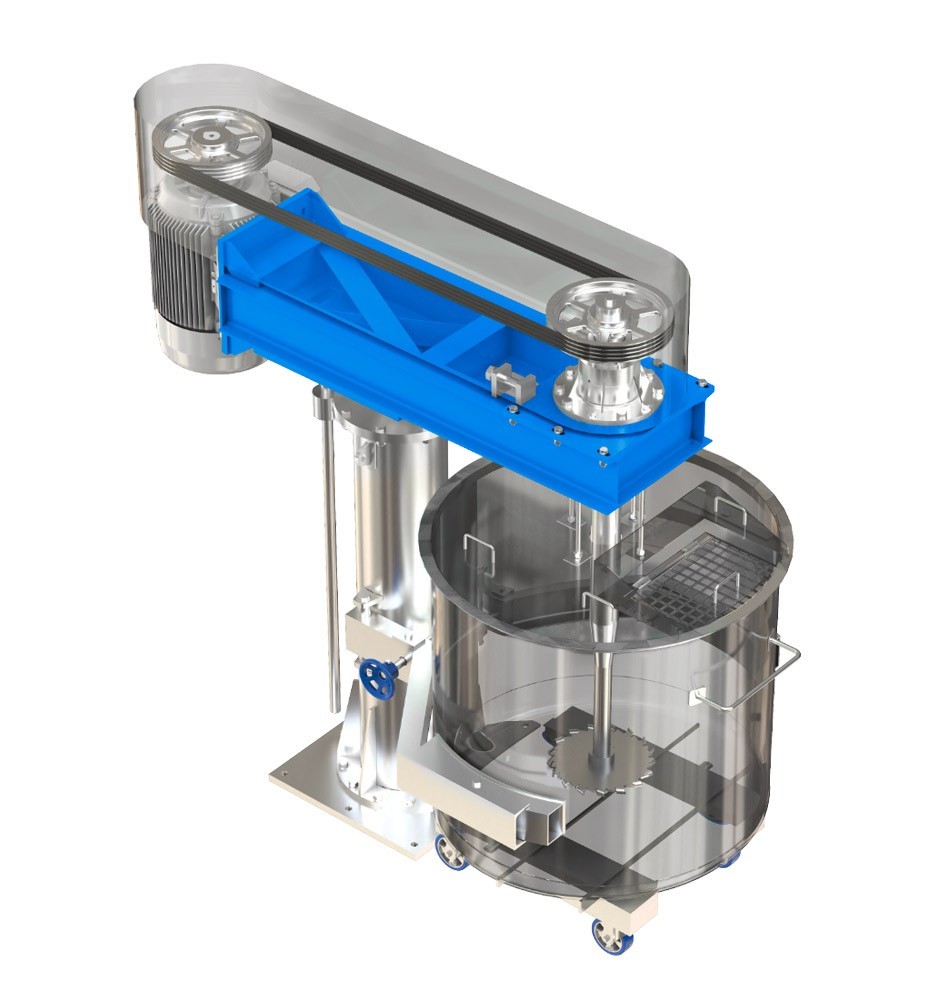

Mixing Mechanism:

High-speed

disperser blade or impeller specifically designed for rapid material breakup

and particle size reduction.

Blade

configurations optimized for achieving efficient dispersion and homogenization

of the material.

Ø

Construction:

Sturdy

construction using durable and corrosion-resistant materials (e.g., stainless

steel, coated alloys) to withstand demanding operating conditions.

Robust design to

withstand the forces generated during high-speed dispersion.

Ø

Adjustable Parameters:

Variable speed

control to adjust the agitator's rotational speed and dispersion intensity.

Options for

adjustable blade height or immersion depth to control the level of shear forces

applied to the material.

Ø

Mounting and Installation:

Easy and secure

mounting on tanks, vessels, or mixing containers.

Various mounting

options available, such as flange mounting or clamp mounting, to accommodate

different equipment configurations.

Ø

Control Panel:

User-friendly

control panel for convenient operation and adjustment of mixing parameters.

Intuitive controls

for starting, stopping, and adjusting the agitator's speed or other relevant

functions.

Ø

Safety Features:

Safety interlocks

and guards to prevent accidents and ensure operator safety during installation,

maintenance, and operation.

Emergency stop

button for immediate shutdown in case of emergencies or unforeseen situations.

Ø

Maintenance:

Easy-to-access

design for routine maintenance and cleaning.

Regular

maintenance recommendations provided in the user manual for optimal performance

and longevity.

Ø

Applications:

Suitable for a

wide range of industries, including chemical processing, paint and coatings,

pharmaceuticals, food and beverage, and more.

Ideal for

dispersing and dissolving materials such as powders, pigments, resins,

additives, and other substances into liquid or solvent.

Please note that the specifications provided are

general and can be customized based on specific customer requirements and the

intended application.

Powerful Dispersion Capability:

The Disperser Agitator is equipped with

a high-speed disperser blade that generates intense shear forces, enabling

rapid material breakup and particle size reduction. It ensures efficient

dispersion and dissolution of materials, resulting in uniform mixing and

enhanced product quality.

Versatile Design:

Our Disperser Agitator is available in different

capacities, accommodating a wide range of batch sizes and production

requirements. It offers flexibility in dispersion intensity and allows for

customization of blade height or immersion depth to achieve precise dispersion

control.

Robust Construction:

Built to withstand demanding operating conditions,

our Disperser Agitator features a sturdy construction using corrosion-resistant

materials such as stainless steel or coated alloys. This ensures durability,

longevity, and consistent performance even in harsh environments.

Adjustable Parameters:

The Disperser Agitator provides variable speed

control, allowing you to adjust the rotational speed and dispersion intensity

according to your specific needs. This flexibility enables fine-tuning of the

dispersion process for optimal results.

Easy Installation and Operation:

Our Disperser Agitator offers easy and

secure mounting options on tanks, vessels, or mixing containers. The

user-friendly control panel facilitates convenient operation, providing

intuitive controls for starting, stopping, and adjusting the agitator's speed.

Safety Features:

Safety is a top priority, and our Disperser Agitator

incorporates safety interlocks and guards to ensure operator protection during

installation, maintenance, and operation. An emergency stop button is provided

for immediate shutdown in critical situations.

Wide Industry Applications:

The Disperser Agitator finds applications

in various industries, including chemical processing, paint and coatings,

pharmaceuticals, food and beverage, and more. Its versatility makes it suitable

for dispersing and dissolving powders, pigments, resins, additives, and other

materials in liquid or solvent.

Experience the exceptional dispersion capabilities of our Disperser

Agitator to enhance your production processes and achieve superior results.

With its powerful performance, versatile design, and user-friendly operation,

our Disperser Agitator is the ideal solution for your dispersion needs. Contact

us today to learn more about how our Disperser Agitator can optimize your

manufacturing operations.

Keywords:

disperser agitator, dispersion, dissolution, powerful

dispersion capability, versatile design, robust construction, adjustable

parameters, easy installation, user-friendly operation, safety features, wide

industry applications, chemical processing, paint and coatings,

pharmaceuticals, food and beverage, material dispersion, product quality,

manufacturing operations.