Industrial agitators are mechanical devices that are mainly used to mix, blend, and homogenize materials in various industries such as food and beverage, chemical processing, pharmaceuticals, and wastewater treatment. They are designed to agitate a medium in a vessel such as a tank, reactor, or mixer in order to achieve the desired results.

Industrial agitators can vary in size, shape and complexity, depending on the task and process requirements. Some of the most common types of industrial agitators include the following:

• Flash Mixer

• Flocculator

• IBC Stirrer

• Industrial Blenders

• Homogenizer

• Dispersers

These machines can be designed with different types of impellers, which are responsible for the mixing action. Some of the impeller types include:

• Propeller

• Anchor

• Turbine

• Paddle

Benefits of Using Industrial Agitators:

Efficient mixing of materials and reduction in process timeConsistent quality and homogeneity of the final productEffective heat transfer and temperature controlReduction in energy consumption and operating costsLower maintenance and repair costsIncreased production capacity and throughput

Improved safety and product quality.

Applications of Industrial Agitators:

• Chemical Processing: Agitators are used for mixing, blending, and reacting chemicals in various stages of production, from raw materials to final products, including adhesives, polymers, paint, and coatings.

• Food & Beverage: Agitators are commonly used in the food and beverage industry for blending ingredients such as sauces, creams, and yoghurt.

• Pharmaceuticals: Agitators play a critical role in the production of pharmaceuticals, from mixing of active ingredients to the final blending of the product.

• Wastewater Treatment: Agitators are used to mix and agitate wastewater to ensure that the solids are evenly distributed, and to promote the separation of solids from the liquid phase.

In conclusion, industrial agitators are essential machines that are used in various industrial applications worldwide. They improve efficiency, reduce costs, and maintain high quality standards during the manufacturing process. When investing in an industrial agitator, it is important to consider the specific requirements of your production processes to ensure that you choose the right type of agitator for your needs.

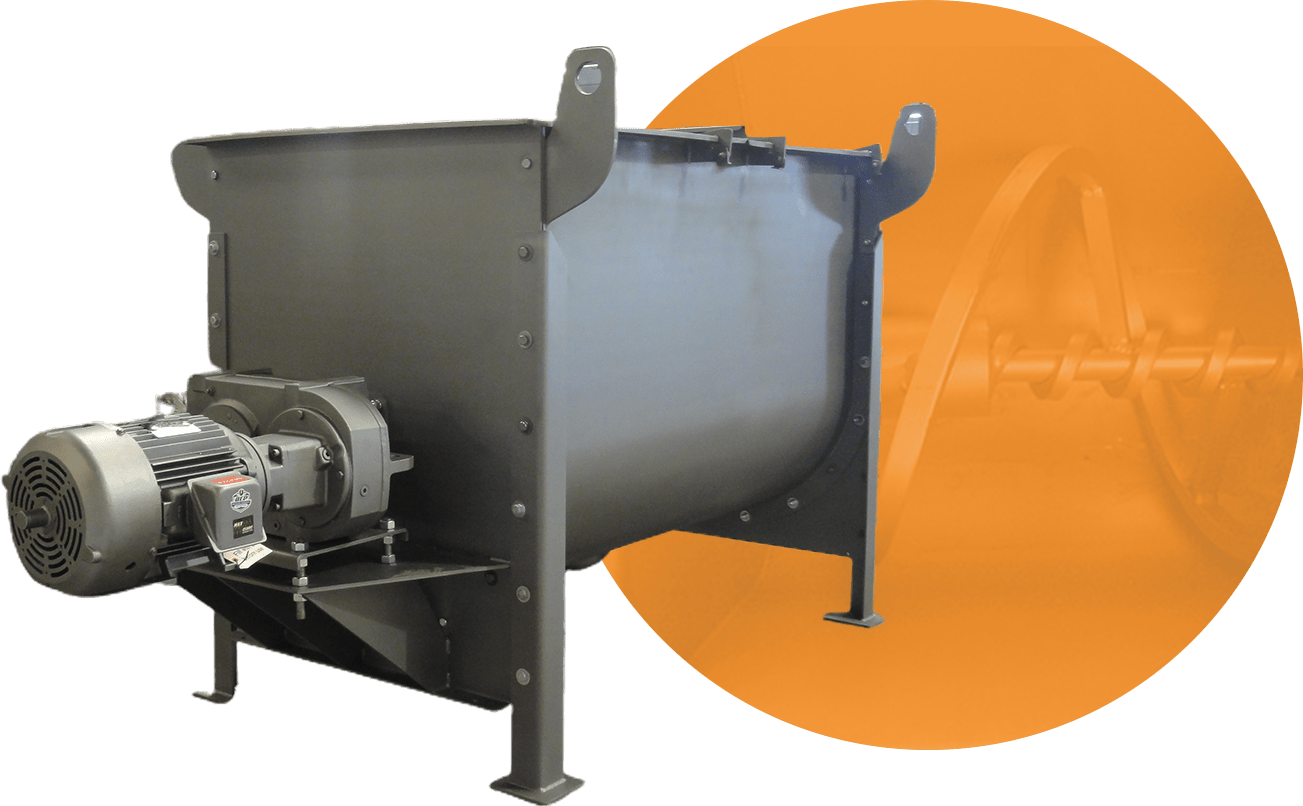

Flash Mixer

View

Flocculator

View

IBC Stirrer

View

Industrial Blenders

View

Homogenizer

View

Dispersers

View